What is a car alternator?

It is a device used in cars to generate the electric current that powers the electrical devices in the car and also charges the car battery. The dynamo consists of a set of moving and fixed parts, including magnets, electrical coils, brush, rotor, and electrical connections.

When the rotor spins, the magnet moves in sync with it, causing an electric current to occur in the electrical coils. Passing the electric current through the brush and electrical connections results in the production of electricity used to power the electrical devices in the car and charge the car's battery. The car's dynamo is an important part in the charging and lighting system of the vehicle.

Car Dynamo Parts

Your car's dynamo consists of several moving and stationary parts. The moving parts include the electrical coils and rotor, while the stationary parts include the shaft, holder, shield, magnetic set, and the main body.

Moving Parts:

1- Electrical Files

The electrical coils are part of the car's alternator components, they are made from thin copper wire wrapped around an iron core. These coils work to generate electric current when the rotor spins and the magnet inside it moves.

The electrical files consist inThe alternatorNormally, there are several coils located in the moving part of the dynamo, and these coils move with the rotor. The electric current that is produced passes through them.

The efficiency of your car's alternator depends on the quality of electrical coils used in it. Typically, these coils are made of pure copper to ensure a good and continuous flow of electricity. The electrical coils are tested before being installed in your car's alternator to confirm their quality and suitability for correct operation.

In general, electrical coils play an important role in the function of a car's alternator. They generate the necessary electrical current to charge the car's battery and operate its various electrical devices.

2- The Rotator

The rotor is an important and vital component in the car's alternator, composed of a laminated iron piece containing a set of magnetic fields. The rotor spins within the magnetic group and moves the magnetic fields inside the electrical coils connected to the vehicle's electrical circuits. This process transforms mechanical energy into electrical energy.

The rotor contains a set of threaded holes around its circumference. These holes accommodate a set of overlapping plated iron, which acts as an internal motor pushing the rotor to rotate. It is necessary to constantly lubricate the rotor and ensure that it rotates smoothly and without friction to prevent damage and malfunctions.

Fixed Parts:

1- The Shaft

The car's dynamo shaft consists of a rotating shaft and a stationary shaft. The rotating shaft is the part that moves and rotates due to the circular motion of the rotor and is connected to the rotor through a set of electrical connectors.

The stationary column contains a set of carbon brushes that consistently make contact with the rotary column to conduct the generated electric current to the electrical circuits in the car.

The rotating shaft is heavily loaded in order to withstand high loads and high speeds of the rotor. It is important to ensure regular maintenance and lubrication of the shaft to achieve optimum performance and prevent failures and damage.

2- The Bracket

The bracket is the part that holds the rotor and the rotary shaft in the car's dynamo. The bracket is installed on the bottom surface of the engine and next to the generator, and it is fixed with special screws.

The mount contains a set of brackets and iron teeth that connect to the engine and secure it firmly. The mount also includes a set of ball bearings that freely carry the rotating shaft within the mount and allow it to rotate smoothly.

It is important to regularly maintain and lubricate the ball bearings to ensure a long life for the bearing and the rotary shaft.

3- The Protector

The protector is the part that shields the rotor and the internal components of the car's dynamo from dust, dirt, and other flying debris. The protector is installed near the rotor and the rotating shaft, and it is designed to match the shape and size of the rotor.

The protector is usually made of plastic or rubber, and it is typically flexible to move with the rotor without sticking to it. The protector acts as a shield for the rotor, protecting it from wear and damage caused by dust and other flying debris, as well as protecting the carbon brushes from dust and damage.

It is important to regularly maintain the protector to achieve optimal performance of the car's alternator.

Also read:"Dynamo Burnout: 5 Symptoms Indicating Damage"

4- The Magnetic Assembly

The magnetic set is a part of the car's dynamo and is considered one of the basic components of this device. This set consists of two permanent magnets, which are placed in a circular shape around the dynamo's rotational column.

This magnetic assembly works on generating electric current in the dynamo through the movement of the mechanical rotor and its interaction with the magnetic field produced by these two permanent magnets.

Permanent magnets are characterized by their ability to maintain the magnetic field they produce once it is created, which makes the magnetic assembly in the dynamo not need an external power source to produce the magnetic field.

5- The Main Body

The main body is a part of the car's dynamo and is considered the primary structure of the device. This component is designed to house all the other essential parts of the dynamo and assists in guiding and supporting these parts in their correct places. The body of the dynamo is typically made from cast aluminum to achieve the necessary strength and durability for this part.

The other parts of the dynamo are installed in the main body using bolts and nuts, and they are securely fastened to prevent any vibrations or damage to the part during operation. The main body can be found at the top of the dynamo and is the part that is installed in the engine.

The main body of the alternator is designed with small openings for air to pass through and cool the part during operation. This part is also designed to be disassembled and reassembled for maintenance and repair of any faulty parts in the alternator.

All these parts interact together to generate the necessary electrical current to charge the car battery and operate various electrical devices in it.

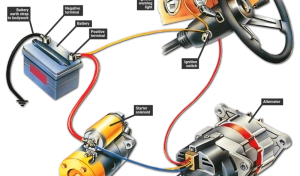

How the car's alternator works

The car's dynamo is one of the most important parts that generates the necessary electric current to operate many electrical devices in the car, such as the lighting system, the battery, and others.

When the engine is started, the rotor in the dynamo is rotated by the action.The mechanical movement of the engine.When the conductor moves in the rotating ring across the magnetic field in the magnetic set, an alternating electrical current is produced.

The resulting electric current is directed to the voltage regulator, which adjusts the charging current to ensure that the car battery remains properly charged. The voltage regulator is typically installed on the bracket and is connected to the rotor ring.

In this way, the necessary electric current is produced to operate the electrical devices in the car, and it is distributed through the electrical wires to the various devices in the car, such as the lighting, sound system, and other electronic devices.

Comments